Wood is a 100% natural and ecological product. However, the process of transforming wood into paper for example, contaminates. Here we will explain the derivatives of wood products.

With the industrialization of the wood sector, several types of wood have been created. Some boards continue to be with a base of natural wood treated and glued in several forms and others are combinations of wood and plastic.

In this article, we will focus only on products derived from wood, and that do not use any type of artificial material.

Summary of the page

- Laths, beams, and sawn wood

- Laminated board

- Three-layer board

- Veneer

- Plywood

- OSB

- Chipboard or Conglomerate

- DM or FDM boards

- Mouldings or profiles

- Paper and cardboard

- Wood end products

Índice de la página

LATHS, BEAMS, AND SAWN WOOD

This is only the process of cutting a log into different sections. There may be a sanding and brushing process in the case of sawn wood. There is also a format of laminated lath. They are used to finish the corners and as support in drawers, etc.

LAMINATED BOARD

It is a board formed by different slats. The measures are usually 240 x 120 x the desired size. It is a board widely used in the creation of furniture.

THREE-LAYER BOARD

It is a board formed by three laminated boards, aiming the middle layer in opposite direction of the strands. This gives much more strength and resistance to the board.

VENEER

Veneer or veneer sheets are obtained through the process of peeling or by the method without relief. It is used to cover other materials or woods that are more economical.

PLYWOOD

Plywood is a board formed by three different veneers. It has a very good resistance and it is very well mechanized with screwdrivers, nails and others. Plywood is generally used in the marine and automotive sectors.

OSB

Board formed by oriented and glued fibers. It is very resistant but also very heavy. It is an economical board and very good insulator. It is often used in the early stages of construction and in businesses but also in homes as decoration.

Chipboard or Conglomerate

Formed by wood residues, crushed, pressed and glued. They are very used for the creation of furniture because they are not very expensive, but they are very heavy.

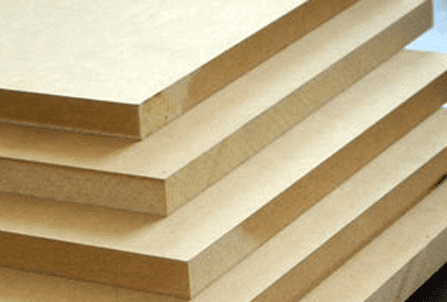

DM OR MDF BOARDS

Board formed with the dust of wood pressed at very high tension. It is a very heavy board: 600-700 km/m³. It has a homogeneous and smooth surface.

MOULDINGS OR PROFILES

They are usually wider than the slats, as well as flatter. They are normally used for decoration of ceilings, doors and walls. It is a style widely used in the nineteenth century and still persists in some countries.

PAPER AND CARDBOARD

The cellulose of the wood is the primary material. To obtain it, it is necessary to pass first the phase of trituration (mechanical) and the cooking (with chemical adhesives). The material is flexible and burns with great ease.

FINAL PRODUCTS IN WOOD

Nowadays, we have created anything with wood. From shelves and furniture to kitchen products, children's toys, sports elements and decoration of all kinds. Because with wood and their derivates we can do almost everything